A foundational challenge to buildings constructed over contaminated soil or groundwater is ensuring that the indoor air will be safe for building occupants.

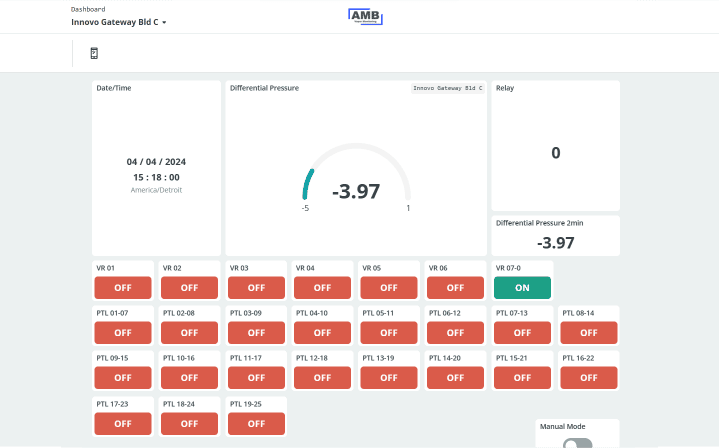

AMB Vapor Monitoring provides its customers with cloud-based control and reporting for their sub-slab depressurization systems. Traditionally, environmental consultants need to visit their client sites in-person to manually collect differential pressure data. Beyond the immense time and costs involved with this cumbersome requirement, the potential for a failure to occur to the sub-slab depressurization system between the duration of collecting differential pressure data without any alerts could put building occupants’ health and safety at risk.

AMB recognized that they needed a revolutionary solution, one that could efficiently collect and record data from a centralized network of 20 to 200+ subsurface differential pressure testing locations along with providing real time failure alerts. They found the answer in Arduino Pro’s versatile and capable technology.

Mark and Adam Bishop, co-founders of AMB Vapor Monitoring, explain how they created a custom solution for their business with Opta and Arduino Cloud, going from idea to installation in a matter of months and building professional, functional dashboards in mere hours: “And it works. It just literally works.” (To find out more about their success story, watch the full-length segment from the 2024 Arduino Days on YouTube.)

The Arduino Pro Opta is a secure, easy-to-use micro PLC with Industrial IoT capabilities, supporting Arduino programming experience and PLC standard languages.

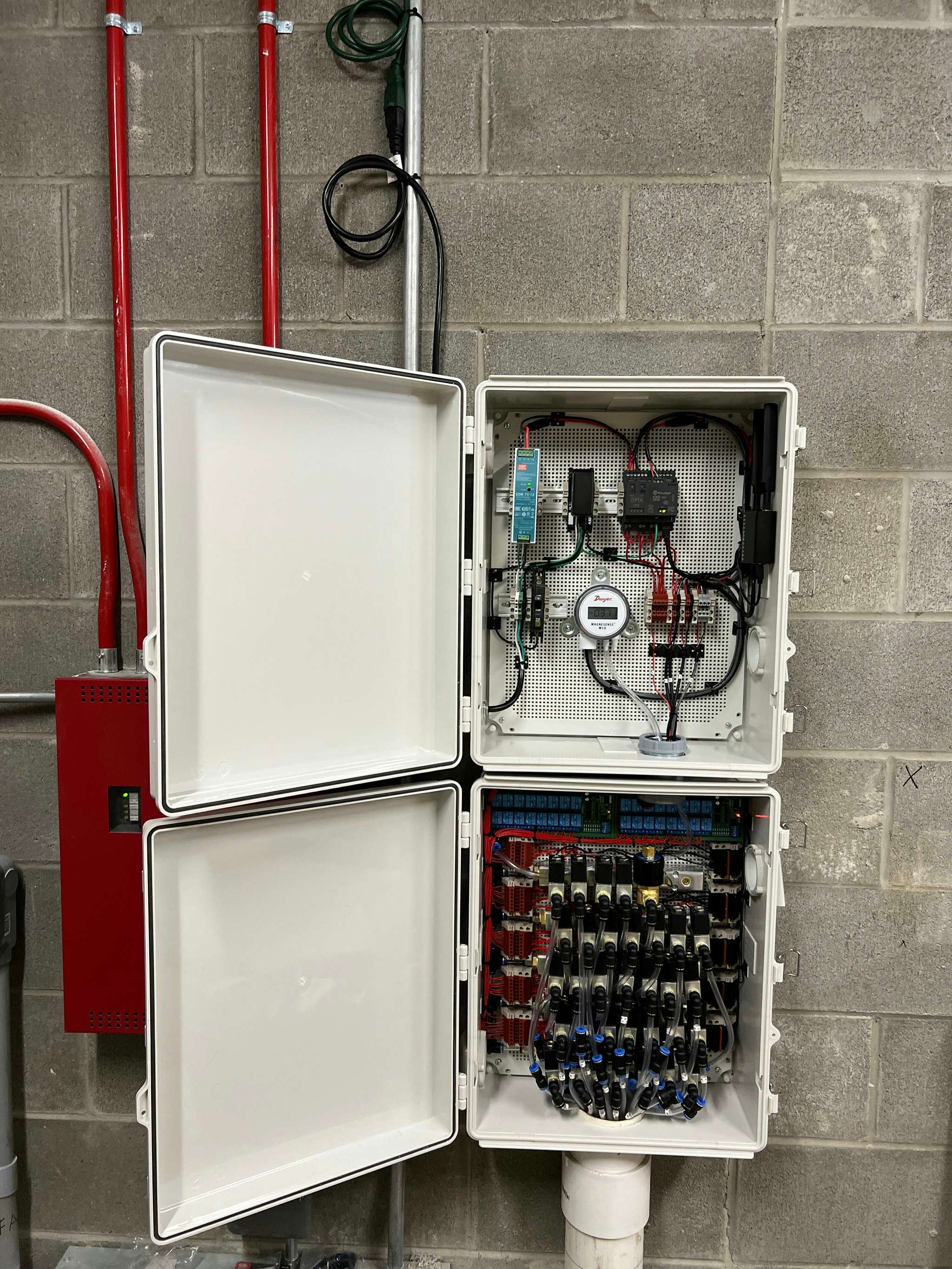

AMB chose to work with Arduino Pro’s Opta micro PLC. They needed a solution that could adapt to various environmental conditions and offer seamless data transmission via cellular connectivity, allowing for real-time monitoring.

Arduino Cloud allowed AMB to move to production quickly, as the final step in the prototyping journey towards creating their own ready-to-use and customizable pressure monitoring system. Now, they can offer clients a complete solution where data is collected, centralized and processed 24/7 – available in real time via intuitive dashboards, easy to navigate on any smartphone or tablet. If any anomaly is detected, the system issues timely alerts that allow for immediate intervention.

Choosing Arduino proved invaluable to AMB’s journey, accelerating their time-to-market and allowing the company to save hundreds of thousands of dollars between licensing fees during the R&D process and web development expenses. Arduino Pro Customer Success was pivotal in guiding the project to viability, mitigating the need for custom cloud solutions. An automation technician within the company leveraged community resources to learn C/C++ and develop the custom application, highlighting the accessibility and support provided by Arduino.

“Once we discovered the Opta, our whole world changed. We went from, ‘I don't know if we can truly do this,’ to ‘I think we can do this in a much quicker timeframe'.”

– Mark Bishop, AMB co-founder

With the foundation of Arduino’s technology in place, AMB plans to expand their portfolio of connected automation products and services.

The company envisions a continued partnership to fully leverage the power of Arduino’s capabilities, with the aim to further enhance sub-slab differential pressure monitoring solutions required by state and federal regulators. Having found the right partner for their endeavors not only transformed AMB’s approach to environmental monitoring, but also set a precedent for the industry by demonstrating how innovation and the right technology can drive efficiency, accuracy, and cost savings while ensuring a safer environment for all.