Optimotion has created an automated, Industry-4.0 wastewater treatment solution to make the environment safer for both staff and community.

CEO Guillermo Guereque, a mechanical engineer with a passion for innovative solutions, founded Optimotion in 2014 as an original equipment manufacturer (OEM). He soon led the company to enter the IoT arena, turning it into a game-changer for industrial clients across various sectors, including automotive, energy and food.

One of Optimotion’s clients, a water treatment chemical supplier, posed a unique challenge. Serving a variety of manufacturing plants, they needed to purify wastewater in compliance with stringent government standards. The traditional manual approach was labor-intensive – in a harsh, chemical-laden environment – as well as error-prone, and lacked the real-time data essential for auditing. So Guillermo decided to develop a smarter, automated solution that could record chemical usage, monitor its behavior, and optimize dispensing.

Optimotion built its solution with Arduino Pro to:

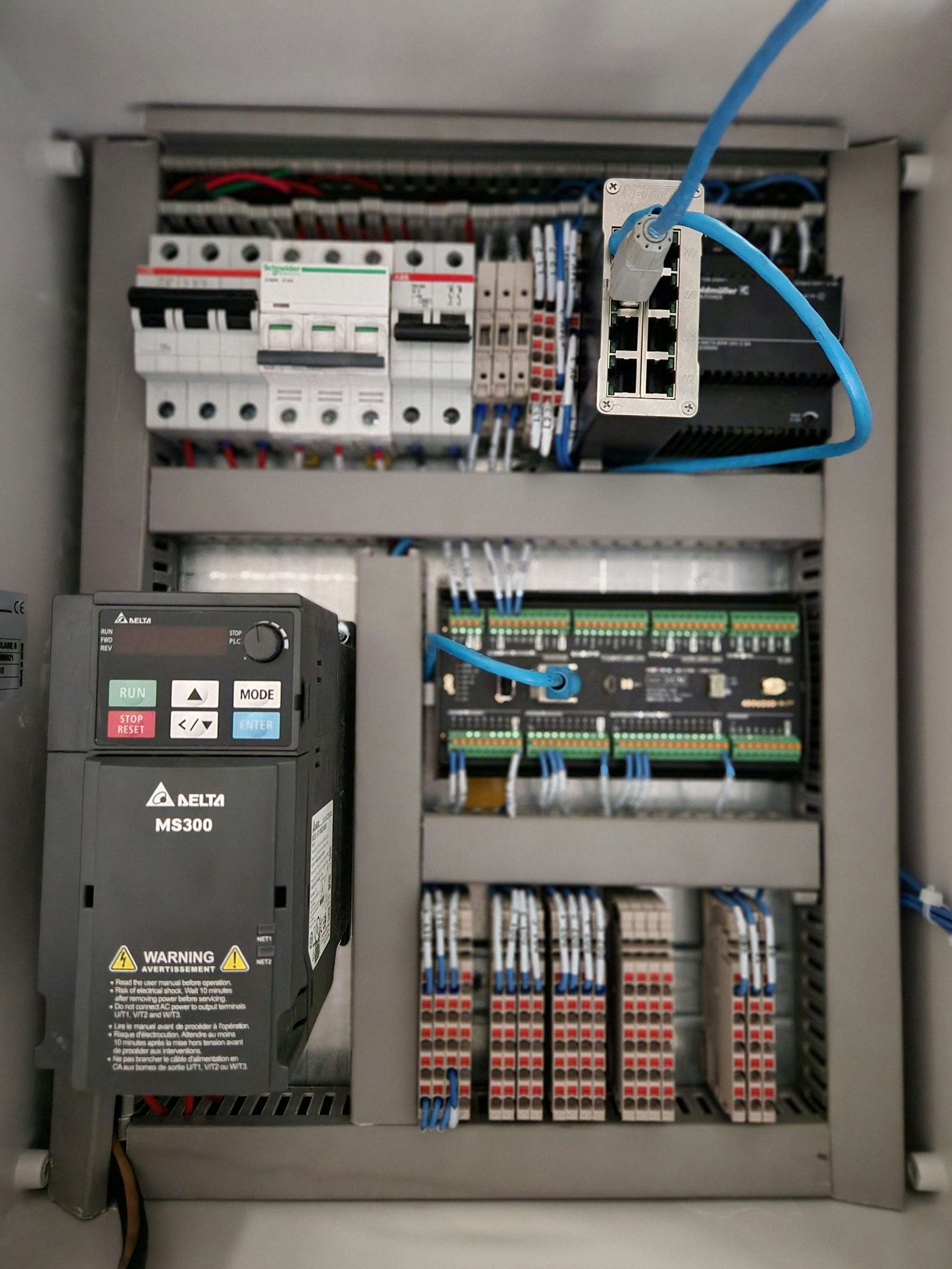

Arduino Portenta Machine Control was chosen – after a year of rigorous testing – for its exceptional data acquisition and robust cloud connectivity, essential for real-time monitoring and control.

With the inclusion of a flow sensor, the Portenta Machine Control precisely measures water flow through pipes and dispenses the required chemicals with outstanding precision. Leveraging advanced processing capabilities, it offers a significantly faster scan time compared to a typical PLC – a critical factor for accuracy, where even minor calibration errors could prove disruptive.

On top of providing an elegant solution to optimize the treatment process and enable compliance with all the requirements to execute this mission-critical task, Arduino’s Portenta Machine Control offered a cost-effective alternative compared to other industrial automation solutions on the market.

The ability to rapidly integrate the Modbus protocol, was also a huge plus. The HMI (Human-Machine Interface) was swiftly developed, displaying real-time values and component statuses – which in turn allow for effortless data management, streamlining the complex task of determining chemical dosages based on flow values.

“We decided to run extensive testing against the Portenta Machine Control for 1 year. It proved to be not only robust, but also the perfect device for this application.”

Guillermo Guereque, CEO of Optimotion

Optimotion’s success story with Arduino’s Portenta Machine Control is emblematic of a shared commitment to innovation and efficiency. Our philosophy of open-source development, community support, and affordability aligned perfectly with the company’s vision of delivering IoT solutions that empower everyone to excel.

Looking ahead, Optimotion envisions further collaboration with Arduino to tackle new challenges and create innovative solutions – taking advantage of the whole ecosystem of hardware components, software tools and cloud services in our ecosystem. Accessing a world of opportunities that are easy to integrate into the future of Industry 4.0 and beyond.