A modular, scalable monitoring solution to constantly and automatically check ventilation is working properly: the key to ensure air quality in medical centers.

Counting on a team of 200 employees and 1,200 doctors, Santagostino operates a network of 35 medical centers in Italy, mainly distributed across Milan, Rome and Bologna. Just over a decade after they began, they are able to offer a wide range of diagnostic tests and procedures – but perhaps the most basic service they need to guarantee is a comfortable and safe environment for the thousands of patients that come to their facilities.

Air conditioning and ventilation have always played an important role in this: while most of us have become hyper-aware of the importance of air quality only after the pandemic, the Engineering & Technical department at Santagostino has always worked hard to ensure the correct operation of these systems.

Their challenge? Staff and customers would often notice if the heating or air conditioning were not regulating temperatures properly, but it could take days or even weeks before a technician detected a malfunction in mechanical ventilation during a routine, on-site check.

The company therefore set out to find a 24/7, remote monitoring solution, which also had to be modular and scalable to adapt to the variety of HVAC systems installed across their centers.

“Our solution is very simple, but not obvious. Using Arduino allowed us to apply it to any type of system – whether analog or digital, made by any brand.”

ANDREA CODINI, CTO AT SANTAGOSTINO

Santagostino developed internally an Arduino-based solution to monitor HVAC systems across 35 locations in Italy, feeding AI the data to detect – and even predict and prevent – any malfunctioning.

The Nano RP2040 Connect, protected by a 3D-printed case, was placed inside heat pumps, A/C units and mechanical ventilation systems at the network’s centers. Regardless of the type, brand and model used at each location, the installation was carried out easily, with no need to involve external specialists or alter the machines in ways that would effectively void their warranty.

The Nano RP2040 Connect’s built-in accelerometer was set to record x, y and z axis parameters every 30 seconds, which are then charted to signal whether the machine is working or not, as well as to detect vibrations. Monitoring which systems are switched on, when, and where, allows Santagostino not only to immediately find unwanted stops, but also to save energy and money by identifying HVAC systems running when not necessary, at night or on holidays. Optimizing schedules also extends the equipment’s lifecycle, with a positive impact on both budget and environmental footprint.

Furthermore, vibrations are analyzed with AI to identify excessive stress on the machines, and trigger timely maintenance or corrective measures. Predicting issues, avoiding faults and being able to act immediately when HVAC systems are not working properly means Santagostino can ensure their centers are always well ventilated and air is optimally filtered.

The software was developed internally: thanks to Arduino’s open source approach and easy-to-program module, Santagostino now owns a proprietary code they can adjust and improve as needed.

Create a high-performance, custom solution that is compact and cost-efficient, Monitor a wide range of systems from different manufacturers, Avoid the risk of voiding the equipment warranty, Maintain its independence from external suppliers, Guarantee staff and clients optimal air quality at all times.

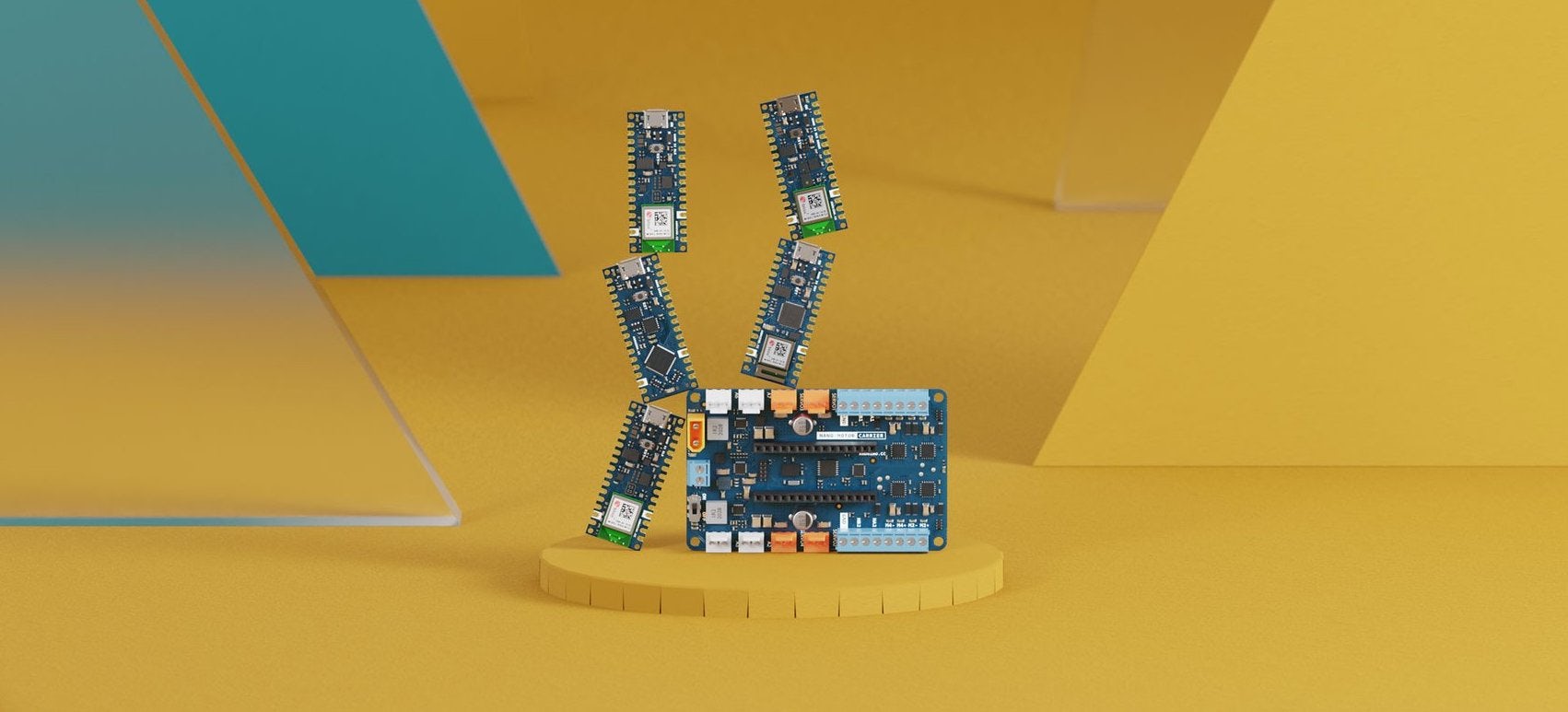

Tiny, powerful and reliable, the Arduino Nano family is perfect for wearables, drones, scientific experiments and any other IoT/AI solution that needs to shrink size, not performance.

Santagostino chose the Nano RP2040 Connect because it includes both a Wi-Fi® module and high-quality accelerometer, while still standing out with an extremely compact form factor and competitive price.

In addition, its ARM processor is able to collect data from Santagostino’s centers, send them to the Edge Impulse platform, and run the ML algorithm that autonomously reads and interprets systems’ operational status.

“More expensive, ready-made solutions have nothing on the Nano RP2040 Connect. And it was so easy to program we were able to code our own solution – which we can update and improve as required, without depending on developers outside the company.”

ANDREA CODINI, CTO OF SANTAGOSTINO

From the entry-level Nano Every to the advanced AI capabilities of the Nano 33 BLE Sense.