Lower expenses, higher data processing speed: a lighter solution for real-time quality testing.

Snaptron is the world’s leading manufacturer of tactile dome switches, dome arrays, and complementary equipment for industries including consumer electronics, aerospace, aviation, automotive, marine, medical, and defense customers. Years ago, they developed the Sapphire Force Testing Machine to test their products and guarantee the utmost quality on the market.

Recently, Director of Engineering Kevin Albertsen realized the solution – dependent on multiple PC/104 cards for each function, stacked on top of a single-board computer – could be optimized by achieving a more efficient, cost-effective implementation and providing real-time data analysis.

“We started by assuming that Arduino makes great products and offers outstanding customer support. We have been incredibly impressed on both accounts.”

– Kevin Albertsen, Director of Engineering at Snaptron

Simple and quick prototyping for an advanced quality control machine opens up a whole new market segment.

“The simplicity and versatility of Arduino platforms allowed us to streamline the prototyping phase, enabling rapid iteration and testing of our ideas. By leveraging Arduino’s extensive library support and open-source resources, we decreased our development time – freeing up resources for other projects,” says Albertsen.

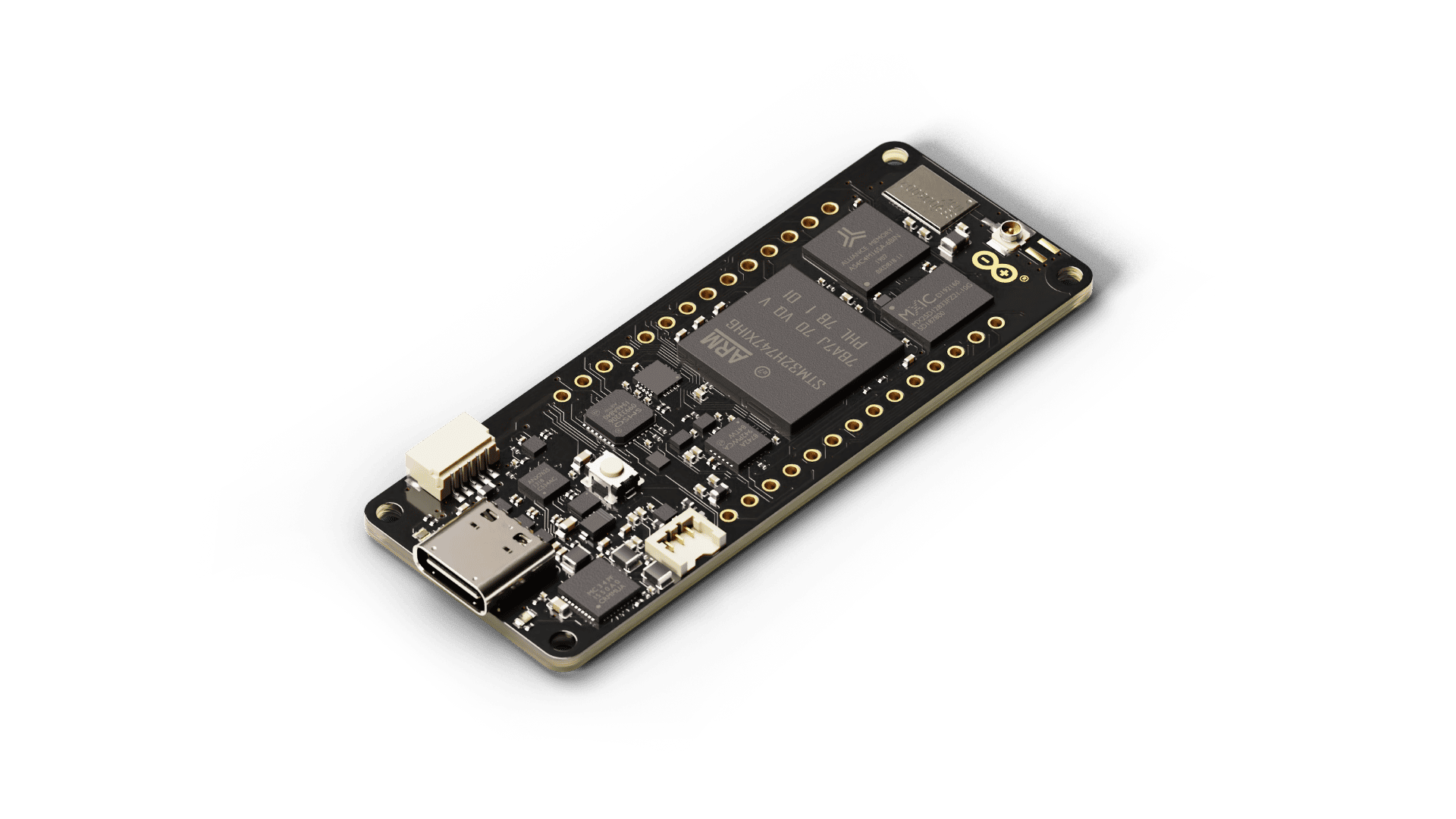

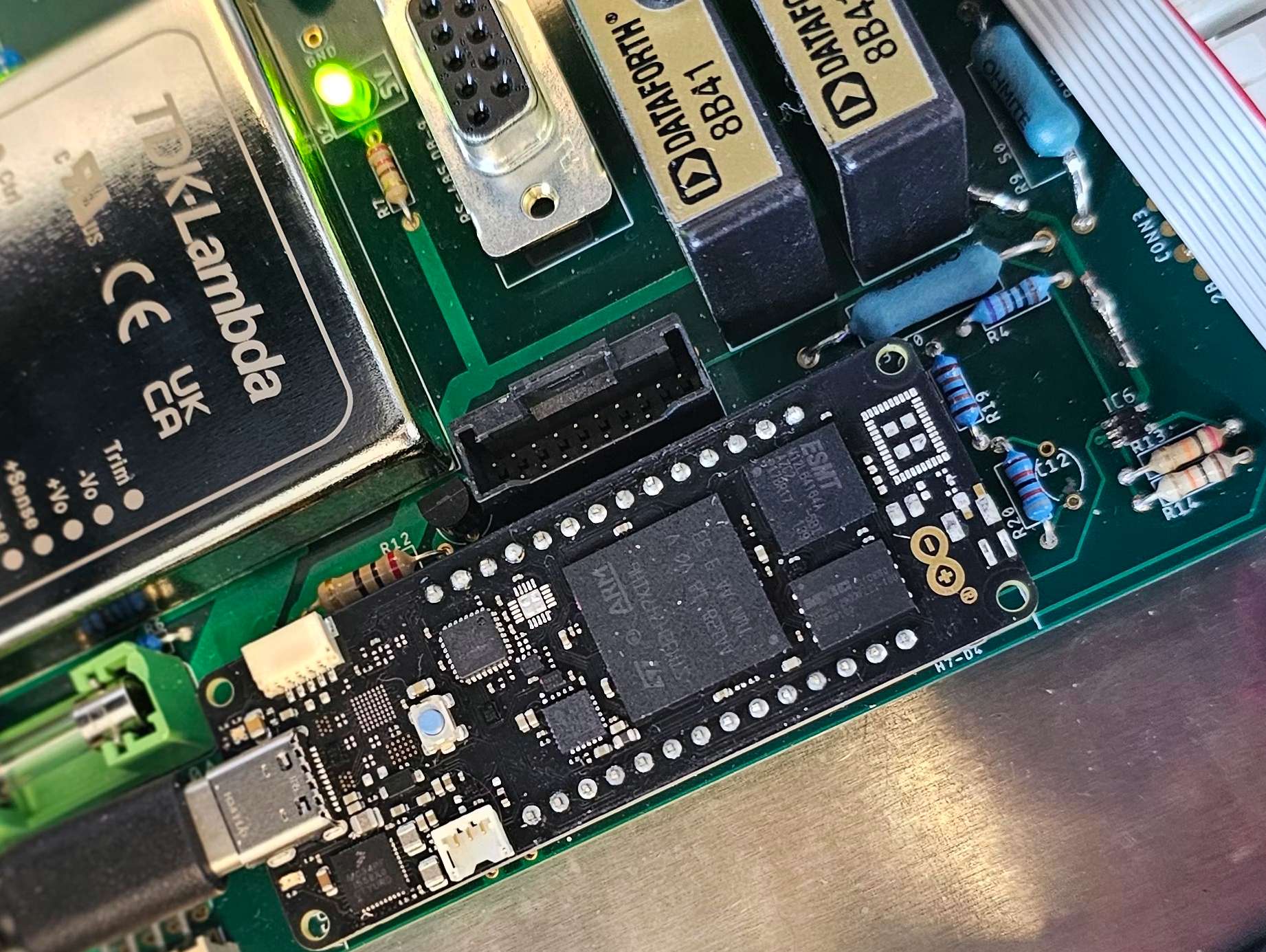

Having identified the Portenta H7 Lite as the best solution to upgrade the Sapphire, Snaptron’s team appreciated the easy data transfer with their single-board computer over the USB interface, and the use of digital and analog connections over low-density connectors, which facilitated low-volume implementation and in-house PCB assembly.

They were also impressed with Arduino’s customer support: “We needed to complete the certification process within a tight deadline, and their team was quick to provide the information we needed on Portenta’s CE certification,” Albertsen notes.

Cost-effectiveness was also a key factor:

“The affordability of Arduino boards significantly reduced prototyping costs and enabled savings that allowed for further improvements, while keeping the overall budget under control,” Albertsen says.

While Snaptron developed the Sapphire machine to support their own quality and compliance processes for characterizing switches, they soon realized customers also needed a force-displacement switch tester for their end-products. This led the company to develop a marketable solution and start a new business line.

Innovating swiftly and effectively to deliver the utmost quality to the market.

“Arduino’s products have given us several options for low-cost solutions in data acquisition, signal processing, and machine control. This ability to rapidly prototype and test has directly translated to higher-quality products; we saw an immediate decrease in go-to-market issues. Overall, Arduino has been a catalyst for our team's innovation, providing the tools and flexibility needed to push the boundaries of our development capabilities. This enables us to continue to innovate and confidently deliver high-quality products to market.”

Snaptron plans to continue to use Arduino products for the data acquisition and machine control on some of its equipment. “Arduino has provided us with an exceptional product in the Portenta H7. We couldn't be happier with our choice,” concludes Albertsen.