The advantages of Industry 4.0 are beyond doubt, but implementing data handling and integration are not always as straightforward.

Techgest, founded in 2000, is a leader in ERP (enterprise resource planning) system integration and custom software development for companies across various sectors, ranging from precision mechanical manufacturing to plastic and rubber molding to fashion and sportswear. A focus on continuous innovation and customer satisfaction has led them to develop their own MES (manufacturing execution system) and WMS (warehouse management system) platform, TechTree, designed to seamlessly integrate ERP software with the production floor.

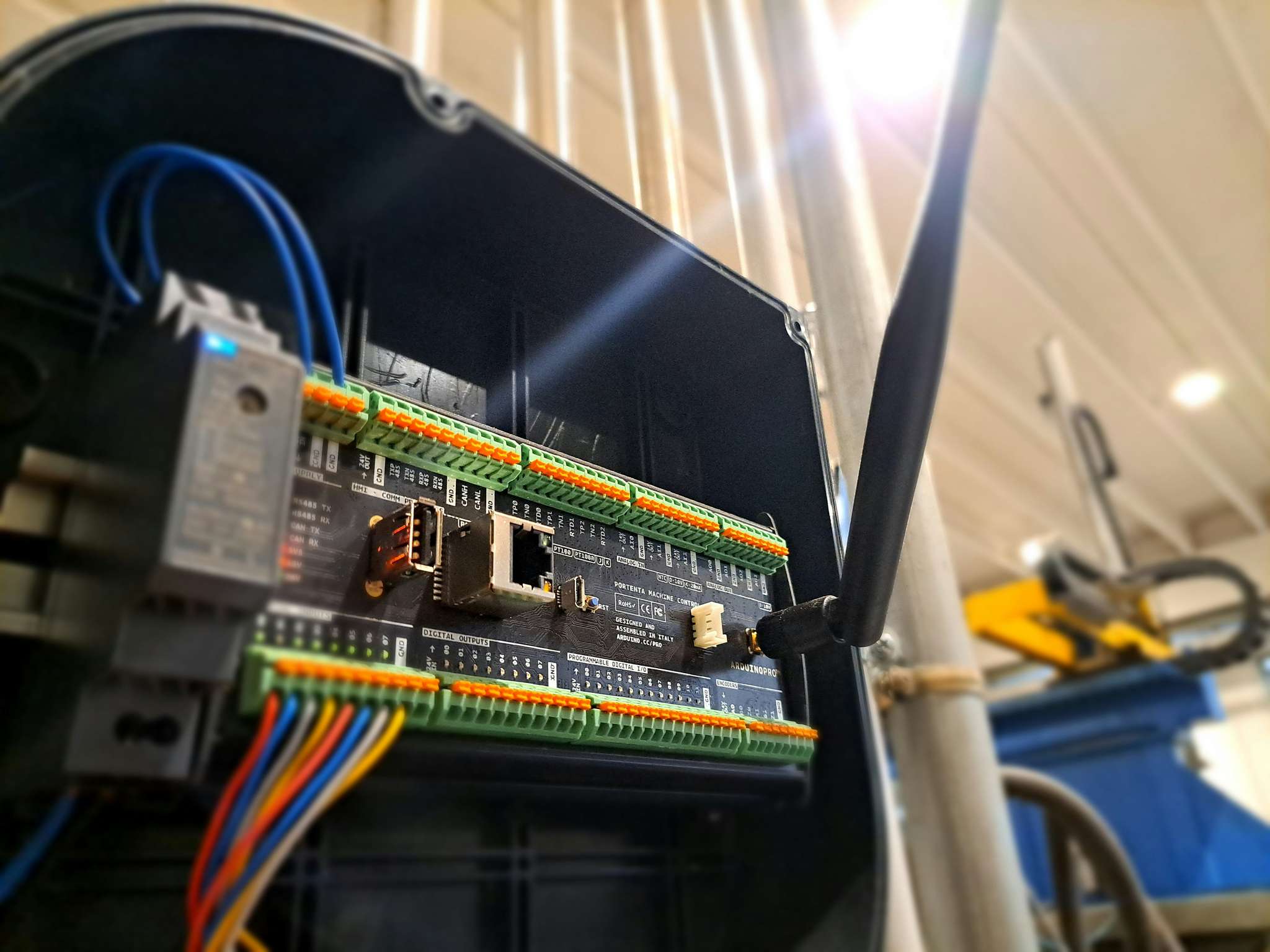

This led them to realize that manufacturing and production companies often struggle with managing the vast amounts of data generated by complex processes. Thus, Techgest identified a need for a simple IO device for automatic data acquisition to enhance their TechTree MES solution. They set out to create a solution that would be easy to install, powerful, and customizable, allowing seamless integration with existing systems without the need for third-party platforms. They called this device TechIO, and based it on the Arduino Portenta Machine Control.

“We evaluated various standard IO interfaces but found them lacking in terms of power and customization. We needed a solution that would allow us to build our own system exactly as imagined, without vendor lock-in. This was particularly important because our client portfolio spans a wide range of industries, each one with their own typical equipment. Arduino’s Portenta Machine Control emerged as the ideal choice.”

– Stefano Girardi, CEO of Techgest

The Arduino Portenta Machine Control was chosen for its customizability, cost-effectiveness, and open-source flexibility.

The implementation process was swift and efficient, thanks to extensive online resources and responsive community support. Techgest integrated the Arduino Portenta Machine Control into their new TechIO device, tested it, and put it into production within mere weeks! This rapid development cycle was crucial in meeting the demand for a quick time-to-market solution.

Compared to traditional PLCs, the Portenta Machine Control offered lower costs and provided a complete and open API interface to interact with any software and hardware. Now, Techgest’s customers can fully integrate their production machines into TechTree, even without communication ports or PLCs. This allows for real-time production monitoring, improved efficiency in energy management and quality KPIs, and significant cost savings – even without expensive retrofits.

One client reported that TechIO allowed them to purchase four new machines knowing the energy savings alone would offset the investment – approximately €1 million – in just 18 months.

The project has had a profound impact on Techgest’s business, boosting customer satisfaction.

“To further enhance operational efficiency and overall productivity for clients, we are now working on new IoT units that use Arduino Nicla Vision with embedded ML algorithms for preemptive quality monitoring, working in synergy with TechIO,” says Andrea Piovesan, CTO of TechTree. “Additionally, Techgest is seeking to extend the benefits of MES to a broader client base by collaborating with innovative and reliable partners to help more companies achieve enhanced operational efficiency and productivity.”