A fully-centralized, low-power, industrial control unit able to drive equipment and machinery.

Enhance the intelligence of your products with the Portenta Machine Control

The Portenta Machine Control adds Industrial IoT capabilities to standalone industrial machinery. It enables the collection of real-time data from the factory floor and supports the remote control of equipment, even from the Cloud, when desired. Thanks to its computing power, the Portenta Machine Control enables a wide range of predictive maintenance and AI use cases. It can be programmed using the Arduino framework or other embedded development platforms.

Find out more about Portenta Machine Control's features, application examples, connectors and other technical aspects in the board's datasheet.

Key benefits:

- Shorter Time-To-Market

- Enhance existing products with minimal effort

- Make equipment smarter to be ready for the AI revolution

- Add connectivity for monitoring and control

- Interact with your equipment with advanced HMI displays

- Tailor it to your needs, each I/O pin can be configured

- Secure and robust by design

- Modular design for adaptation & upgrades

- Open new business model opportunities (e.g. business-as-a-service)

Add Industrial IoT capabilities to standalone industrial machinery:

Upgrade equipment or develop new distinctive products

The Portenta Machine Control enhances existing products with minimal effort, allowing companies to implement a standard platform across different equipment models. It is now easy to create an infrastructure of interconnected machines, which can be controlled onsite or via the Cloud when needed; moreover, human-machine interaction can be further enahnced via mobile apps thanks to Bluetooth® LE connectivity. Arduino is a popular technology that has been adopted by many engineers worldwide to reduce time to market; there is a huge number of ready-to-use software libraries that make it easier to interact with sensors and actuators.

Improve customer experience

Monitoring customer usage of equipment can provide valuable production data, useful to minimize downtime, perform predictive maintenance, and carry out calibration activities. Customers can be supported remotely, in order to optimize field engineer workload as well as spare parts availability. In addition, the constant monitoring of the equipment parameters often makes achieving industry certifications easier.

Tailor it to your needs

The modular design is ideal for upgrades and adaptations. Since each I/O pin can be configured, the Portenta Machine Control can be highly customizable while allowing companies to avoid vendor lock-in. Our hardware is robust and secure by design. Many corporations have chosen Arduino Pro solutions to improve manufacturing processes and enhance their products and services.

Application examples

- Batch Freezer

- Clipper Machine

- Cartoning Machine

- Form & Seal Machine

- Gluing Machine

- Pastes Divider

- Electric Oven

- Labelling Machine

- Mixer

- Liquid yeast Machine

- Laser Diode Epilator

- Tempering Machine

- Gas Filler

- Washers & Dryers

- Retarder Proofing Cabinet

- Vacuum Homogenizer

| PROCESSOR | STM32H747XI dual Arm® Cortex®-M7+M4 32 bit low power Arm® MCU (Portenta H7) |

|---|---|

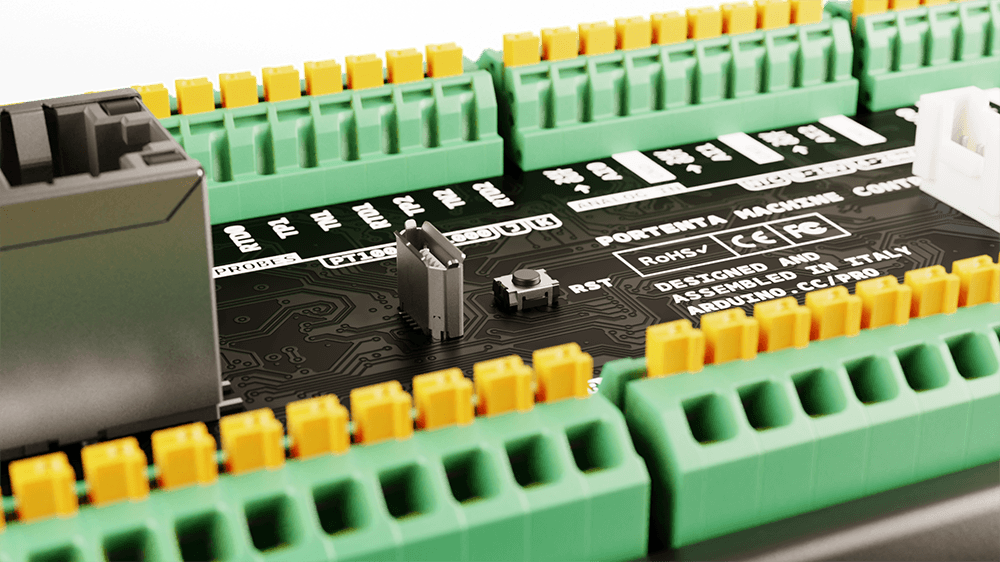

| INPUT | 8 digital 24Vdc, 2 channels encoder readings, 3 Analog for PT100/J/K temperature probes, 3 Analog input (4-20 mA/ 0-10 V/NTC 10 K) |

| OUTPUT | 8 digital 24Vdc up to 0,5 A (short circuit protection), 4 analog 0-10 V (up to 20 mA output per channel) |

| OTHER I/O | 12 programmable digital I/O (24 V logic) |

| COMMUNICATION PROTOCOLS | CAN BUS, Programmable Serial port 232/422/485 |

| CONNECTIVITY | Ethernet, USB, Programming Port, Wi-Fi®, Bluetooth® LE |

| MEMORY | 16 MB onboard Flash memory, 8 MB SDRAM |

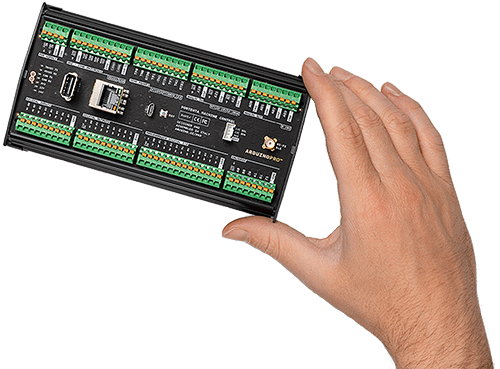

| DIMENSIONS | 170 x 90 x 50 mm |

| OPERATING TEMPERATURES | -40 °C to +85 °C (-40 °F to 185 °F) |

| POWER | 24 V DC +/- 20% |

| CONNECTOR TYPE | Push-in terminals for fast connection |