Inefficiencies in production lines can lead to frequent downtime and reduced productivity.

Many interconnected issues contribute to making OEE implementation a critical issue today:

- Lack of Real-Time Data: Absence of real-time visibility into machine performance makes it difficult to identify the root causes of any inefficiency.

- Manual Data Processing: Reliance on manual data entry and analysis, prone to errors.

- Interoperability and Scalability Challenges: Difficulty in integrating different OT technologies and in economically scaling with increasing data volumes.

- Skills Gap: Shortage of skilled technical workforce for implementing OEE solutions.

The potential financial impact of not having a real-time OEE measuring system in place is huge.

- Downtime Costs: Lost production time and idle workforce.

- Maintenance Costs: Higher expenses due to reactive and unplanned maintenance.

- Quality Costs: Increased scrap and rework, customer rejection.

- Opportunity Costs: Missed production targets, reduced market competitiveness.

- Operational Inefficiencies: Inefficient resource utilization, ineffective decision-making.

- Compliance and Regulatory Costs: Regulatory penalties, audit failures.

Investing in OEE systems can instead optimize production efficiency, enhance competitiveness and reduce costs in the long term. These solutions are part of a broader shift towards Industry-4.0 models, which according to McKinsey may lead to ”30 to 50 percent reductions in machine downtime, 10 to 30 percent increases in throughput, 15 to 30 percent improvements in labor productivity, and 85 percent more accurate forecasting.”

Optimotion built its solution with Arduino Pro to:

An advanced – yet easy and cost-effective – way to integrate IoT technologies, cloud computing, and data analytics.

Optimotion is a Mexican company specialized in providing consulting services and solutions for the advancement of industrial automation and digitalization through world-class technology. As an Arduino partner, they brought together different elements in this proposed system for OEE.

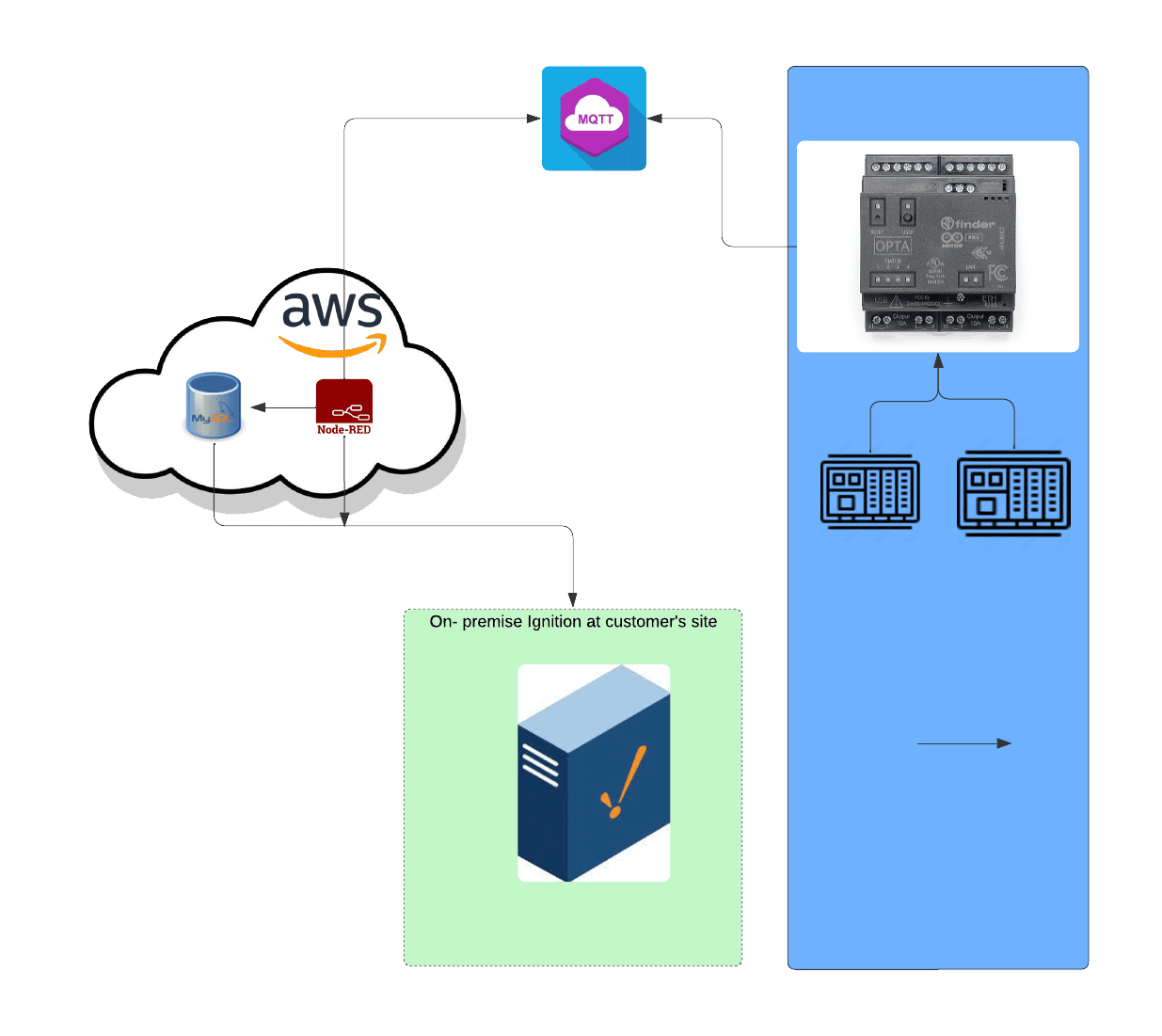

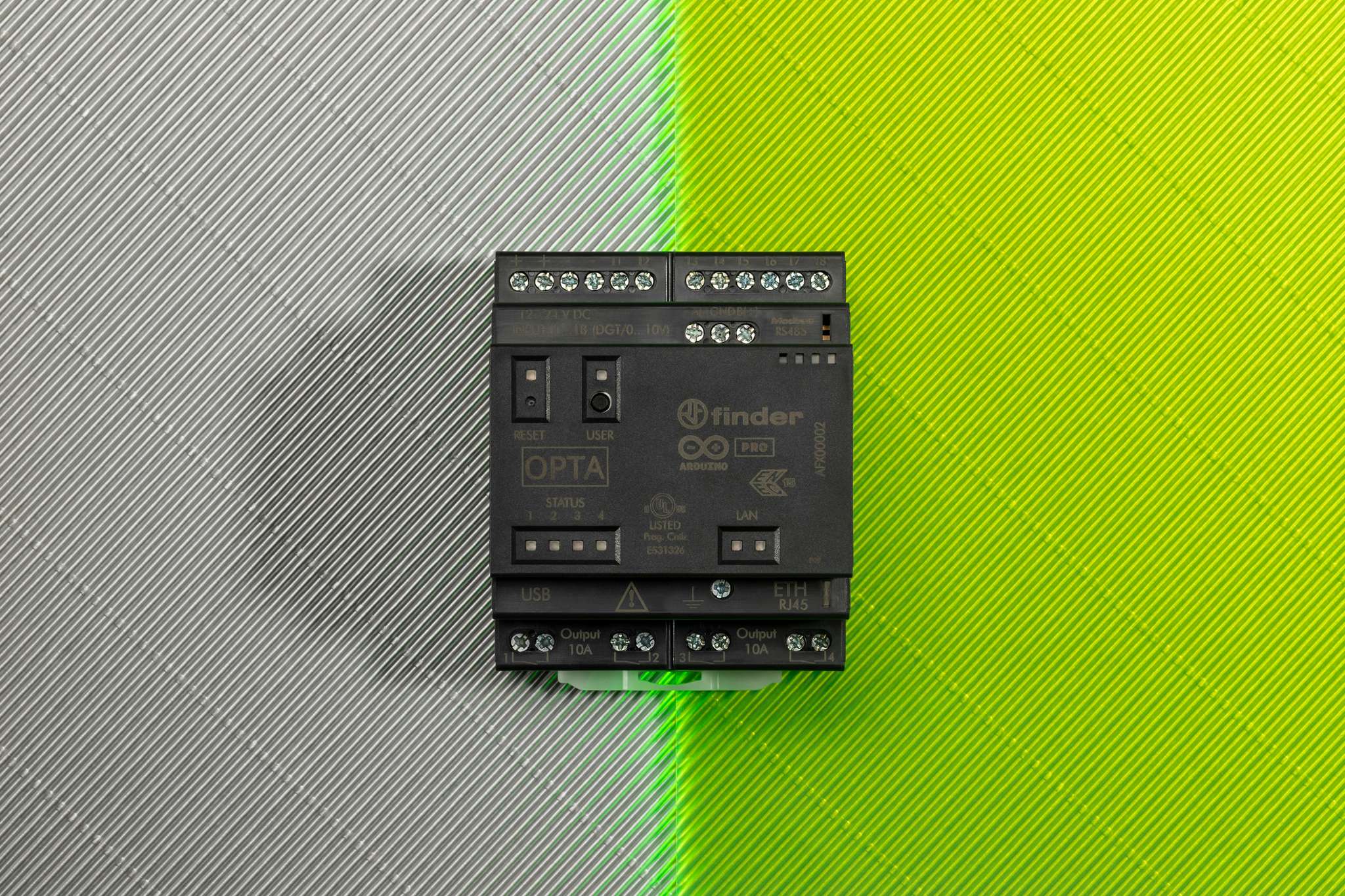

Arduino Opta Integration

Multiple Arduino Opta are deployed to collect real-time data from machines on the shop floor. These micro PLCs are cost-effective and easily integrate with existing machinery – offering the flexibility needed to acquire OEE data in different ways.

MQTT Communication with AWS Cloud

The MQTT protocol is utilized for efficient communication between Arduino Opta and an AWS cloud instance. This ensures seamless real-time data transmission to the cloud.

AWS Cloud Architecture

An AWS cloud instance is set up with a MySQL database and Node-RED instance. MySQL stores incoming data, while Node-RED processes the data, calculates OEE, and inserts it into the database.

Ignition Visualization

Ignition is deployed on-premise to connect to the MySQL database hosted on AWS. It provides intuitive dashboards and reports for real-time visualization of OEE metrics, enabling operators to monitor machine performance effectively.

At the hardware level, Arduino Opta acts as a data concentrator with its powerful dual-core processor. It gathers data using Modbus TCP and RTU and is programmed to be an MQTT gateway to the broker, which can be any choice, including AWS.

Node-RED serves as the “Productivity Engine,” subscribing to MQTT OEE topics, transforming data into useful historic data, and publishing information models. Ignition subscribes to these topics for visualization purposes.

Interested in finding out how this solution can benefit you? Contact us.

"Arduino products and solutions are integral and crucial to our business. They address our core challenges and needs, and their open-source nature and strong community support have enabled us to develop solutions with unprecedented speed, delivering true value to our customers.”

– Guillermo Guereque, CEO of Optimotion

Arduino Opta takes the benefits of OEE to the next level.

Cost Reduction

- Data Acquisition: A powerful data concentrator for less than $300.

- Information Modeling: Easy and secure data modeling with Arduino IDE and MQTT.

- Maintenance Costs: Open standards prevent vendor lock-in, reducing maintenance expenses.

- Expertise: Easier learning curve for automation engineers, fostering innovation.

- Licensing: Reduced licensing costs by 30-40%, with improved scalability to IIoT solutions.

Enhanced Production Efficiency

- Real-Time Monitoring: Immediate visibility into machine performance metrics.

- Automated Data Processing: Eliminates manual data entry errors and delays.

- Scalable Infrastructure: Easily scalable to handle increasing data volumes.

- Interoperability: Seamless integration with various OT technologies.

- Skill Accessibility: Utilizes widely known technologies, easing the skills gap.

Implementing Arduino Opta with Ignition for real-time OEE monitoring, companies can significantly enhance production efficiency, reduce costs, and maintain a competitive edge in the market. A crucial investment for optimizing production processes and ensuring long-term success.